The SDS.TBM module captures the position and installation data during ring construction in real-time. Thanks to the interface with VMT’s TUnIS Ring Sequencing, orders in the storage can be triggered directly from the TBM. All data come together in the SDS database promptly.

Benefits

- The installation location of any segment can be traced at any time

- Smooth advance of TBM thanks to automatic, error-free segment ordering by the TUnIS Interface

- The interface ensures that design requirements and other conditions that define the ring sequences can be precisely implemented

- No more expensive, time-consuming risks during delivery and installation

Functions

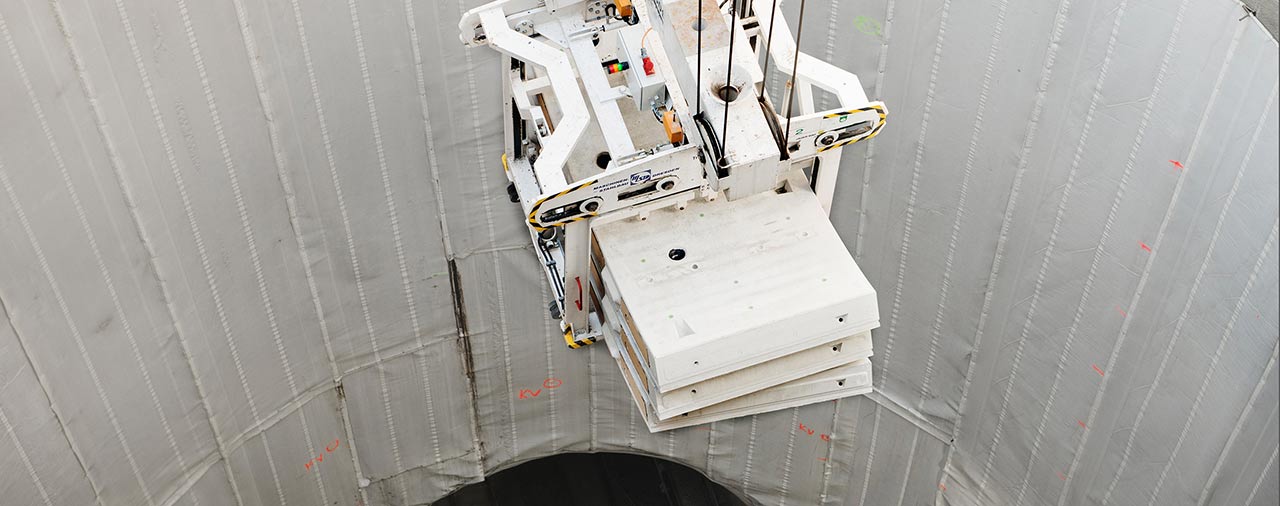

Capturing, documenting and archiving the precise position and installation data of each segment simplifies and speeds up error diagnosis if there is any damage in the tunnel. The ring order is forwarded from the TBM straight to the crane operator as an instruction to store-out. Finally, the TUnIS interface ensures that both the availability of the various ring types and the current order and delivery status are displayed at the TBM.

Module characteristics

- Number of TBM modules required depends on the number of TBMs

Options

- Offline damage recording for tunnel acceptance

Interfaces

- Interface to the TBM’s TUnIS Ring Sequencing

- Interface to data management system, Herrenknecht.Connected – a joint system solution from VMT and Herrenknecht

Get further information about

SDS.TBM

SDS.TBM