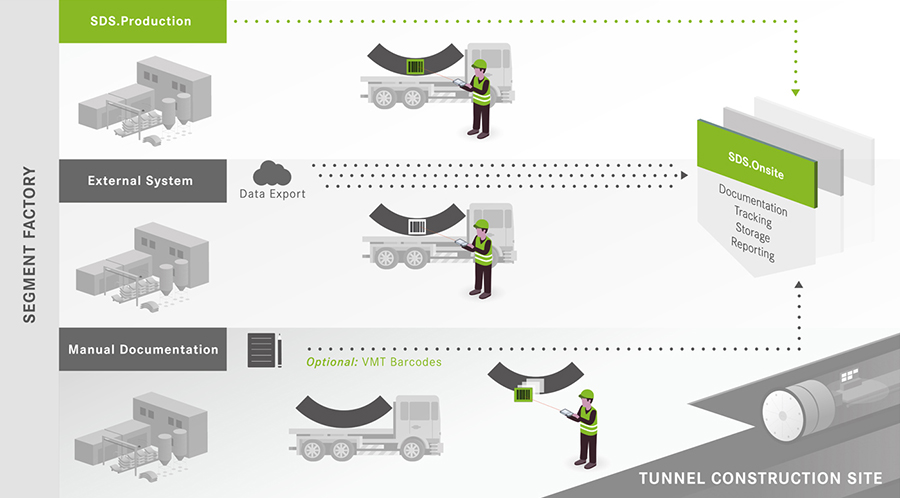

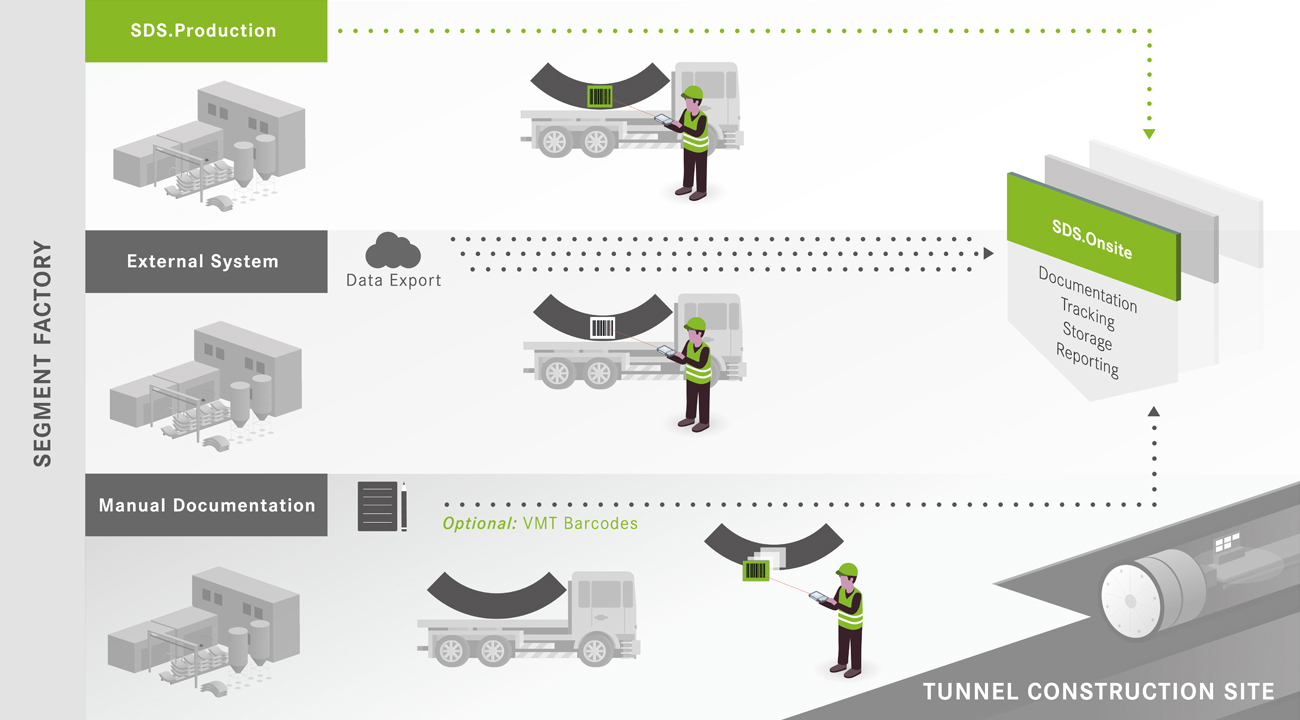

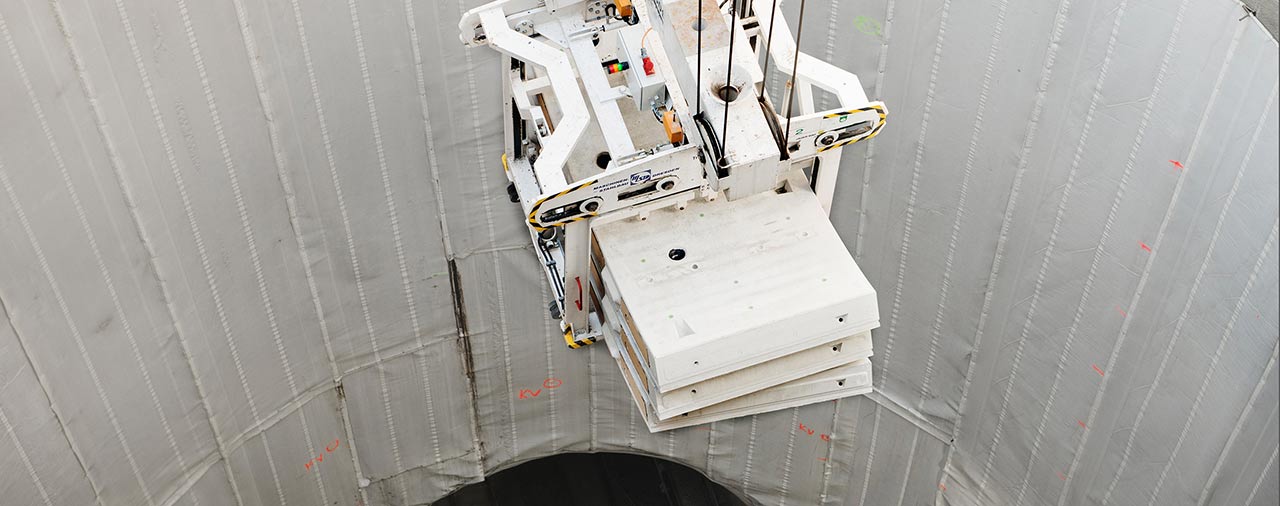

SDS.Onsite is a stand-alone solution for the tunnel construction site. It manages and documents all segment movements and processes during its jobsite acceptance, storage, transport into the tunnel as well as its final installation at the TBM.

Benefits

- Integration of available production data from any segment data system

- Full transparency of storage inventory at any time

- Maximum exploitation of storage capacities

- Seamless documentation of damages and damage handling including damage classification and picture function

- Avoidance of wrong deliveries to the TBM (damaged segments or segments not in line with the planned ring design)

- Provision of lifetime quality records for each segment

- Guarantee of conformity with your clients’ documentation standards

- Fast and reliable error diagnosis in cases of tunnel damage.

Functions

With each arriving segment, either the existing barcode is scanned or a new label printed. Each work step is documented using mobile devices. External production data can be handed over to SDS via CSV import. After the final installation, the system provides a lifetime quality record for each individual segment.

Interfaces

- Visualisation of data in data management system, Herrenknecht.Connected – a joint system solution from VMT and Herrenknecht

- Interface to VMT Navigation System for automatic ring ordering corresponding to tunnel alignment

Ultimate Flexibility

SDS.Onsite can be linked to any other segment management system or generate its own barcodes to assure unique identifiability. Therefore, it can be scheduled independently from the precaster at an early stage or together with the TBM.

SDS.Onsite

SDS.Onsite