The SDS.Production module supports production planning and ensures compliance with defined quality and documentation standards. SDS manages both stationary and carousel production.

Benefits

- Reduction in repair, reject and removal costs: through monitoring and direct feedback, SDS can prevent errors before they happen (wrong reinforcement in the mould, wrong concrete mix, etc.)

- Easier and faster training of new employees: SDS sets out defined stages on the hand-held scanner and takes users through all work stages

- Time is saved by part-automation of the documentation: the system creates absolute transparency about the state of the production process at all times

- Facts-based reporting to the client: thanks to evaluations in seconds and complete, seamless site documentation

Functions

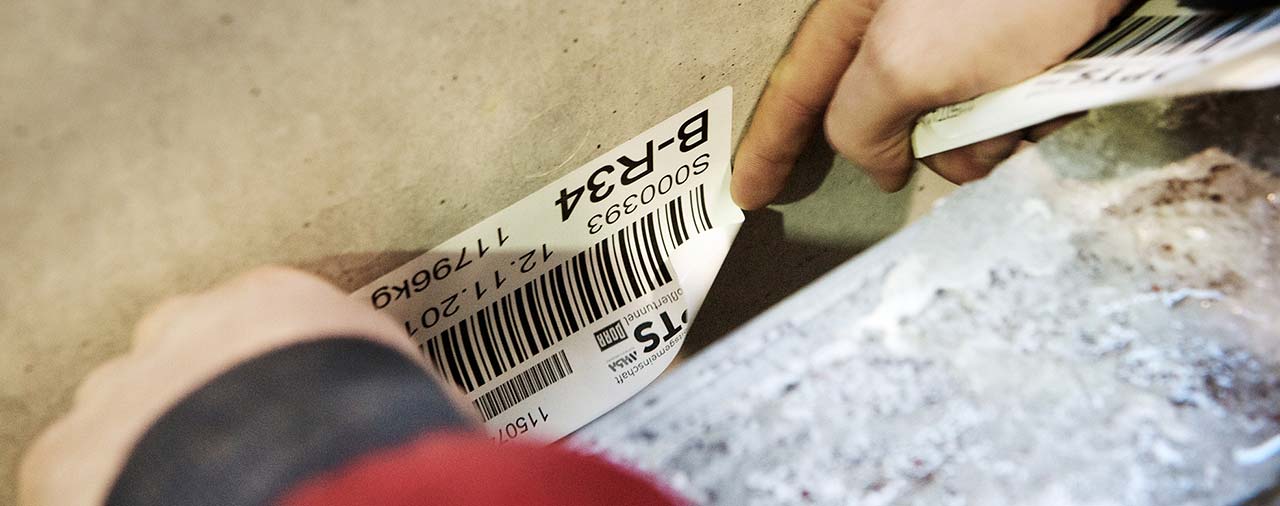

For identification, each segment is provided with a barcode label/RFID tag with its own individual dataset, in which information such as the reinforcement used, tools, concrete composition and geometry of the segment etc. are recorded using scanners and interfaces. Alongside this documentation function, every work stage and all the components are specified and monitored by the system → production errors are avoided.

Damage caused to a segment can be recorded, photo- graphed and classified in the database using scanners → the delivery of faulty segments is prevented.

At the press of a button, the software can also prepare all sorts of evaluations and reports which can be used by the people responsible as an important basis for discussions and decisions.

Module characteristics

- SDS-Stationary for stationary production

- SDS-Carousel for carousel production

Options

- Temperature sensors for the curing chamber

- Quality control through 3D measurement using the supplementary LIS product

- Synthetic label/RFID tag for long-term identification of segments after installation

Interfaces

- Communication with an ERP system (e.g. SAP)

- Interface to the concrete mixer for part-automation of concrete ordering

- Interface to existing heat sensor technology

- Interface to data management system, Herrenknecht.Connected – a joint system solution from VMT and Herrenknecht

Further Information about

SDS.Production

SDS.Production